Chevy Astro Camper Van Build: Electrical Wiring

Chevy Astro Camper Van Build Phase 10: Electrical Wiring

Tools & Materials

Materials

Blue Sea Systems 12v Outlets

Blue Sea Systems 2-Socket Panel

100a Mini ANL Fuse Holder

12-10 AWG Ring Terminals 1/4″

12-10 AWG Ring Terminals 3/8″

12v LED Light, Flush Mount

12v DC Dimmer Switch

Dimmer Switch For LED Puck Lights

Spax Construction Screws

5/16″ Grommets

Heat Shrink Butt Connectors

Spade Connectors Kit

Wire Loom

14 Gauge Stranded Electrical Wire

Non-Twist Wire Connectors

Painter’s Tape

Gorilla Glue

Battery Post Extenders

Tools

Dewalt Cordless Impact Driver

1/4″ Drive Quick Release Bit Extension

Craftsman 3/8 Drive Drill

Craftsman Socket Set

Dewalt Oscillating Tool

Dewalt Compound Miter Saw

C Clamps

Heat Gun

Wire Stripper/Crimper

Klein Tools Cable Cutters

Step Bit

Video – Chevy Astro Camper Van Build: Electrical Wiring

Project Overview: Electrical Wiring

**I am not an electrician, and the information I’m sharing here in this post is not meant to be regarded as professional advice. I will not be held liable in any way for harm done to yourself or others by use of the information presented here in this post.**

I’m splitting up the electrical wiring phase of the project into two posts: this one (Electrical Wiring) and Power Center. The power center is where most of the major electrical components are housed, and requires building a cabinet. So I figure, that ought to be its own post. Here, I’ll be talking about the wiring of the 12v electrical system (the lights and outlets), as well as running the 4 gauge wires for my DC Charger (in the next phase) from the back of the van to the engine compartment. This will allow me to charge the house battery via the van’s alternator.

Electrical wiring is something that is not done all at once in a van build. You will find yourself doing a little bit of wiring throughout much of the van build process. I ran what wiring I could prior to installing my walls and ceilings. Then, I connected my 12v lights and sockets while installing my walls and ceilings. Then I had to build my “power center”, where I installed more outlets. Then I built some shelving, and these shelves had more lights, outlets and switches installed in them that needed wiring as they were built. So you see, wiring is something that should be considered throughout the entire build.

For my 12v lights and outlets throughout the van, I’ll use 14 gauge wire. 14 gauge wire is capable of handling up to 15 amps, which is about double what I could possibly use, given my setup, for any one outlet. All of my wiring runs will be less than 20ft, so amperage loss over long runs is not much of a worry.

All of my outlets will be Blue Sea Systems 12v Outlets. Blue Sea Systems makes marine grade electrical components, which means they are a little more water friendly than typical household electrical equipment. I’ll have several 12v sockets throughout the van in various locations. I’ll use 3w LED puck lights in the ceiling, which I’ll control with a dimmer switch. I’ll also have some small LED lights that I’ll build into the shelves by my bed, and I’ll control these with a dimmer as well.

Running the 14 Gauge Electrical Wire

The first step in electrical wiring is figuring out where you are putting what, electrical-wise. Where will I install my 12v outlets? How many will I need? What type of things I will I be plugging in, and how much current will they draw? These are all questions you will need to figure out before moving forward with your electrical wiring.

Now that I have my wall insulation in, I can install my electrical wiring over this. You can read up on the debate between stranded wire and solid wire for your van build, but I chose 14 gauge stranded wire. Mainly, because it’s more flexible, and infinitely easier to run in a van build than solid wire.

I know where my power center will ultimately go, which will house my lithium battery, dc charger, fuse panel etc, so all of the 14 gauge wires that I’m running for my 12v circuitry will all be routed to the same place: the back of the van, on the passenger side. I run wires through the beams on the ceiling to get to the driver’s side, and just use some tie wraps to keep them in place here. I had to drill through the metal beam a couple of times for the wire run, and I used rubber grommets here to protect the wire from the sharp edges of the metal along the hole.

I route the wires through hollow parts of the body where I can. This is pretty easy to do throughout much of the van, especially in the rear. The wires are well protected in here as well and don’t require much work to secure. Tie wraps work pretty well here.

Some of the wiring I’m doing requires some splicing. A good example of this is the shelves I’ll build at the head of my bed. I’ll run one 14 gauge wire here, which I’ll splice off into three 12v outlets and two LED lights. I use some non-twist connectors for an easy, push-in splice job.

The wiring for the lights is done in a daisy-chain fashion, so I run one wire from the power center to the first light, then cut short sections of wire to connect to the next light in the chain, and so forth. I use painter’s tape to tape them wires to the ceiling for now, until they are ready to be covered with cedar planks.

I’m still not exactly sure where all of the components of the power center will actually go, so I make sure to leave a bunch of extra wire rolled up at the ends of my runs to the power center, just in case.

Installing the 12v Outlets

Installing the 12v outlets requires something a little different at each mounting location. Some are easy, and some have less clearance on the backside. The 12v outlet at the head of my bed is a good example. The 12v outlet is a cylinder that’s a few inches long and about the diameter of a quarter. It fits into the square hole in the body, just below the bottom cedar plank on the wall above. However, it needs just a little more depth. I can’t make that hole any deeper, since that’s the outer skin of the van, but I can add a spacer between the cedar plank and the outlet’s mounting plate. This will raise the surface that the outlet sits on, and allow it to fit the depth.

In the photo above, the 12v outlet is wired up and the cedar plank is ready to go up on the wall. Notice the grommet in the wall to protect the wire. I used spade connectors to connect the wires to the 12v outlet terminals.

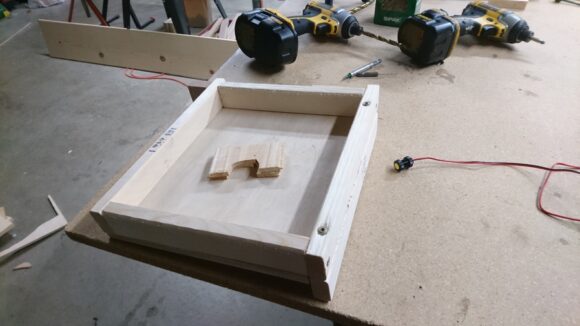

I made this wood spacer to go behind the outlet’s mounting plate to give me extra clearance in the rear

In the photo above, you can get a better look at the wooden spacer I made here to be able to get the depth behind the wall I need to fit the 12v outlet. I used a belt sander to smooth the edges out as needed, to fit the shape of the mounting plate.

The above photo shows the wiring leading to two 12v outlets built in to the shelves at the head of my bed. I split the wires off here to provide power to two separate outlets.

Install LED Puck Lights

The wiring of the LED puck lights is easy: connect the red wires to red wires, black to black. So… there’s a pair of positive/negative wires coming into the first light, from the power center. I’ll strip off about 3/8″ from the end of my 14 gauge wire, and slide both wires into their own 2-port non-twist connector. Now if you’ll remember, I already cut wires to connect the rest of the LED lights, and taped them to the ceiling. So, all I need to do is take one end of the wire taped to the ceiling and insert them into the non-twist connector port connected to the first LED light. Then, connect the other end of those wires to another 2-port connector, and connect to the second LED light. Just keep moving down the line and connect all of LED lights together in the same fashion.

Install Dimmer Switch For LED Puck Lights

I had to wait until my shelves were mostly complete to install the Dimmer Switch For LED Puck Lights. I used my oscillating tool to cut a nice square hole in the wood for the dimmer. The dimmer switch goes in-between the power center and the LED puck lights, so I just made a cut in my wiring at the appropriate location, and wired up the light. Your dimmer will have specific instructions for wiring, so follow the wiring instructions of your specific model.

Install LED Lights In Shelving

I had to build some special wooden pieces to mount my LED light under my shelving at the head of my bed. There is a certain amount of depth to the light, so I need to build up some space to gain the height I need. Much of the details here lies in the woodworking, rather than the wiring.

With the light mounted, I ran the wiring behind a piece of trim that I sanded the corner off of, to make a recessed area for the wires to sit behind.

Install Dimmer For Shelf Lights

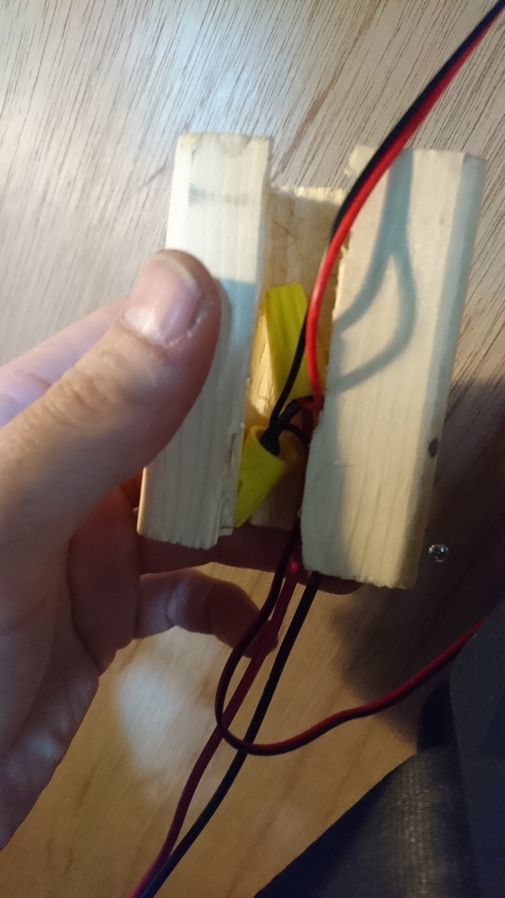

The dimmer switch is a tiny little square piece, and I struggle to come up with a clean way to mount it. I end up taking a small block of wood and cutting a hole in it to fit the dimmer. I took some time to get the fit right, but it was tight and secure in the end. I also added some gorilla glue to bond the switch to the wooden mount.

Next I screw the wooden mount for the switch into the wall. I use two drywall screws for this. Be careful not to go too tight and crack your mounting piece, or the planks.

Protect Exposed Wiring

For some reason, instead of using some type of junction box, I made some funky wood pieces to protect a couple of the connections in the wiring behind the driver’s seat. I took a drill to a 2×3 block of wood, and drilled out some cavities for the wiring to pass through. I don’t recommend this, but it worked, and saved a trip to Home Depot.

Run 4 Gauge Wire For Alternator Charging

In the next phase of the van build, I’ll build the power center and will be installing a DC charger (more on how that works in the next phase). I’ll run the heavy-duty 4 gauge cables for that now. What I’m doing here with the cables is connecting the DC charger that I will be installing with the vehicle’s battery, under the hood.

I used some flexible conduit to protect the 4 gauge cables as I ran the along the roof, alongside my side door, over to the head liner. I used some tie wraps to strap the conduit to the ceiling.

Next, I’ll need to run the cables above the headliner over to the A pillar. The A pillar is the part of the vehicle’s body that runs between the windshield and the front doors. This piece is usually held on by some clips, or possibly screws. Remove this and run the cables down the A pillar, and put the trim piece back on to cover up the wires.

Next, I use a step bit to drill a hole through the firewall. I don’t want the sharp edges of my hole cutting the cables, so I insert a plastic plug into the hole. Then, I cut slits in the face of the plug and run my cables through that. That way, they are protected by plastic on all sides.

Finally, I pull the cables through the engine bay. I’ll install a 100a Mini ANL Fuse Holder and fuse in between the positive cable and battery terminal. This protects the DC charger from a high voltage spike. The negative cable gets hooked up to the negative terminal. I added some Battery Post Extenders to make it easier to add the extra connection to the post. When adding “accessory” connections to side post batteries, you may find yourself running out of threads for your bolt to grip after adding extra thickness (ring terminals, etc). The extenders help overcome that issue. But I’ll leave this disconnected until I’m ready to connect it to the DC charger, in the next step.

Previous Van Build Project: 9 – Solar Panels | DIY Stealth Camper Van Build Index | Next Van Build Project: 11 – Power Center

Leave a Reply