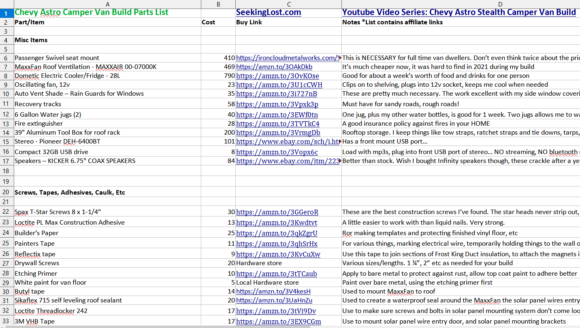

How Much Did It Cost?? Complete Camper Van Build Parts & Materials Spreadsheet

One of the first questions people ask me about my Chevy Astro camper van build is, “How much did your build cost”? This really depends on a few things… will you be doing all of the work yourself? Do you have all of the necessary tools already, or will you be buying some/all as you go? The easiest way to discuss the total cost of my build is probably to just list the parts & materials, and take tools out of the equation. So without further ado, here’s my complete parts & materials spreadsheet for my Chevy Astro camper van build:

As you can see, my total cost for all parts and materials in my Chevy Astro camper van conversion was around $7500.

- For a detailed look at my van build, check out my Chevy Astro DIY Stealth Camper Van Build video series.

- For for written instructions on the build process with photos, parts/materials/tools lists for each phase of the build, see my Astro/Safari Camper Van Conversion page.

You’ll notice I didn’t list a cost for a lot of the wood I used, and that’s because I had a lot of it on hand already. Figure around $300 for the high end of what the wood and lumber should cost in this build. Lumber prices were quite high in early 2021 when I built my van, and should be lower now. Besides the lumber, the list is pretty complete and should give you a good idea of what kind of cost is involved to build out a camper van like mine.

Other costs not calculated in this van build spreadsheet are maintenance costs. If you’re building out an Astro or Safari van, chances are, it will need some sort of mechanical work done before you hit the road… tires, tune up, suspension work… something. Or maybe your van needs a LOT of work. But that’s a cost that varies from van to van, each one will be different. If you aren’t taking care of the mechanical work upfront, before starting your build, it would be wise to set aside a generous budget for maintenance work after the conversion is complete.

Another cost to factor in is paying others to do parts of the build you can’t. Most DIY van builders try to do as much of the work as they can themselves, but you may run into projects that you need to sub out. For example, welding is something most DIY’ers aren’t going to be able to do themselves, unless you just happen to be a welder by trade. Or perhaps you aren’t comfortable with the electrical wiring aspect of your van build, and decide to pay an electrician. These jobs can quickly become expensive when you rely on others, so make sure to set realistic expectations for your van build based on your abilities, and your budget.

Building your own camper van is a huge project, but you can do it. Do your research, ask questions, watch youtube videos (like mine!) and learn all you can about what you want out of your van and what your options are for achieving that vision. Good luck with your build, get out there and make it happen!

Chevy Astro Camper Van Build: Tool Box

Chevy Astro Camper Van Build Phase 19 – Tool Box

Tools & Materials

Materials:

Aluminum Tool Box

Angle Aluminum

Tools:

Dewalt Cordless Impact Driver

1/4″ Drive Quick Release Bit Extension

Craftsman 3/8 Drive Drill

Craftsman Socket Set

Drill Bit Set

Tape Measure

Video – Chevy Astro Camper Van Build: Tool Box

Project Overview: Tool Box

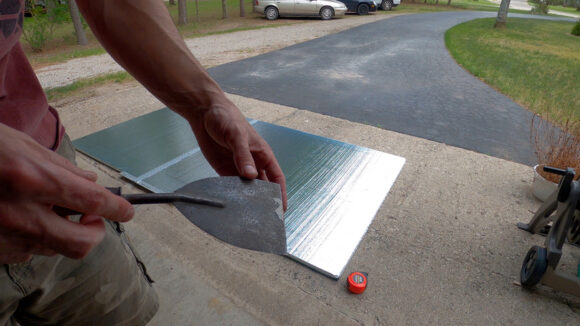

I’ll be installing an aluminum tool box on top of the van for extra storage. I came up with a mounting system that involves a single piece of angle aluminum and a couple of nuts & bolts.

Choosing The Right Size Tool Box

I wanted to keep the height of the tool box lower, and have the box fit mostly beneath the top of the roof rack. Of course, if the tool box weren’t higher than the roof rack, it would only be 5 inches tall. My van already scrapes the bottom of the garage door when pulling it into a standard garage, so no matter what size tool box I go with, the van will either need to be parked outside or I will need to remove the tool box if I want to park it inside a garage. The dimension of the tool box I bought are 39″Lx13″Wx10″H.

Tool Box Mounting System

I want to mount the tool box on top of the roof rack, but the tool box is only supported by one of the rack’s bars. There is nothing underneath the tool box where it butts up against the side of the roof rack. So, I decide to use angle aluminum for this. I’ll bolt a piece of angle aluminum to the roof rack, and the bottom part of the angle aluminum’s L shape will face towards the middle of the van. This provides the support for the tool box to sit on top of, and for the tool box to be bolted into.

The tool box is also mounted to the one roof rack rail that runs underneath it. I’ll just drill a hole through the tool box and into the rail, and use some sheet metal screws to secure it.

Using The Tool Box

I use the tool box mostly to to things I should carry in the van (like jacks, tow straps, etc) but don’t want cluttering up the inside of the van. The flip side is that these things can be heavy, and you don’t want too much weight on the roof of the van, making it top heavy. Probably less of an issue in an Astro van compared to the high profile vans like the Sprinter and Promaster. Either way, I do try to be conscious of the weight I put up there. Also, too much bulk in the tool box forces the lid up on the sides a little, and it’s possible for rain to get inside if the lid is forced up too high.

To get inside the tool box, I stand on the floor of the van’s side door entry. This gives me enough height to see inside.

I have taken the tool box off multiple times, so I could store it inside a standard garage. I have to remove everything inside, but it’s not too bad. It’s a 10 minute job.

Previous Van Build Project: 18 – Cell Signal Booster | Van Build Project Index | Next Van Build Project: 20 – Repairs

Chevy Astro Camper Van Build: Cell Signal Booster

Chevy Astro Camper Van Build Phase 18: WeBoost Drive Reach Cell Signal Booster

Tools & Materials

Materials:

Tools:

Dewalt Cordless Impact Driver

1/4″ Drive Quick Release Bit Extension

Craftsman 3/8 Drive Drill

Craftsman Socket Set

Drill Bit Set

Tape Measure

Screwdriver

Video – Chevy Astro Camper Van Build: Cell Signal Booster

Project Overview: Cell Signal Booster

The setup for the cell signal booster is fairly simple. There’s the signal booster (amplifier) and two antennas that connect to the signal booster. One antenna runs to the outside and picks up the signal, send it to the amplifier, and another cable sends the signal to an interior antenna for your devices to pick up. I’ve heard good things about these cell signal boosters, which is why I invested the money on one. And they are expensive. So, it better work!

Mounting The WeBoost Signal Booster

Installing the WeBoost cell signal booster is a little more difficult than it needs to be, but it’s till not too hard. It’s just that, the unit doesn’t have any type of mounting plates/holes or anything on it to assist with mounting. The instructions say to place it under your seat, and maybe velcro it to the floor. Um, no.

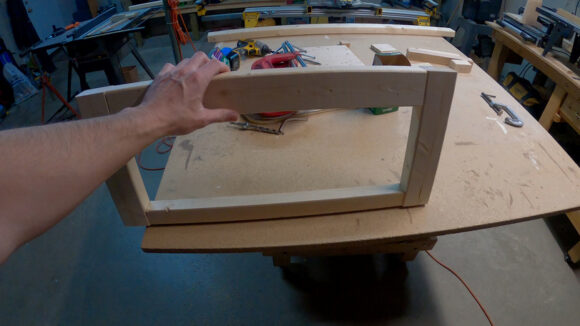

Instead, I mount my signal booster inside a cubby hole on the side shelving area when I open my side door. I use some mood pieces to fit snugly on top and bottom of the signal booster, and screw these in place. Then, I cut a (roughly) 1/2″x1/2″ piece of wood about 6″ long, and run this vertically over the signal booster to hold it in place.

Mounting The Outside Antenna

The WeBoost instructions say to mount the exterior antenna somewhere free of obstructions on the roof. Makes sense. I place mine in the very back, above the rear doors. The instructions also say to route the antenna’s cable under the weather-stripping, which seems highly suspect to me. Underneath is the sheet metal, with some paint over it. Not sharp, but with some force on it, maybe sharp enough to break that cable someday. For now, I run some duct tape over the cable as I route it along the inside of the sliding door over to the weather-stripping, and then some more duct tape over the sheet metal where the cable gets routed over it. Since my signal booster is right here by my side door, it’s easy to route the cable behind my shelving here into the cubby hole where the signal booster is mounted.

Mounting The Inside Antenna

Mounting the inside antenna is even easier. This antenna comes with some two-sided adhesive tape for mounting. I place mine along the top of my shelving, just below the ceiling, above the signal booster.

Using The Cell Signal Booster

The WeBoost booster’s power cable comes with a little on/off switch mounted at the plug, so I leave my signal booster plugged in to it’s outlet at all times. It takes maybe 10 seconds max after flipping the switch to ON for the booster to pick up the signal and amplify it. Usually, 2-5 seconds. While the signal booster is booting up and acquiring signal, the indicator light on the signal booster flashes red and green. After a few seconds, it should become solid green to indicate it’s working properly. If it’s solid red, there’s a problem. Try moving the outside antenna, unplugging the signal booster’s power cord and antenna cords.

The WeBoost cell signal booster draws a surprising amount of electricity, around 2 amps. Therefore I only turn it on when it’s really needed.

Yes or No: Does The WeBoost Drive Reach Cell Signal Booster Work?

Yes, it does. I used the WeBoost Cell Signal Booster for 5 months straight last winter and it consistently boosted 1 bar of 4G to 2-3 bars, 2 bars to 3-5 bars, etc. And the speeds increased noticeably too. More often than not, it turned an unusable “quasi 4G” signal into a good internet connection, usable for working remotely if needed. The bottom line is that it works, and although it was expensive, it does it’s job well.

Previous Van Build Project: 17 – Media Center | Van Build Project Index | Next Van Build Project: 19 – Tool Box

Chevy Astro Camper Van Build: Media Center

Chevy Astro Camper Van Build Phase 17: Media Center

Tools & Materials

Materials:

Android TV Box

5v DC Power Cord For Android TV Box

Anker 36W Dual USB Car Charger Adapter

4TB Portable HDD

Shock Cord

HDMI Cable

Tools:

Dewalt Cordless Impact Driver

1/4″ Drive Quick Release Bit Extension

Craftsman 3/8 Drive Drill

Drill Bit Set

Tape Measure

Screwdriver

Video – Chevy Astro Camper Van Build: Media Center

Project Overview: Media Center

Since I’ll be using a computer monitor instead of a smart TV, I’ll need some sort of “smart device” to run my media center. My first thought was a Raspberry Pi, but hen I found something even simpler… an Android TV Box. It does just what it sounds like; it runs android and runs apps that allow you to watch or stream media. I found a power cord to run it off of DC current, so powering it is not an issue. I will be able to plug in an external HDD that I can load up with movies, TV shows and whatever, for the times (most of the time!) when I don’t have internet.

Testing The Media Center Setup

When I first received my android TV box, I did most of the setup inside the home. I tested that it could read USB flash drives with movies and media files, tested that it could power and read my external HDDs, and learned the layout of the operating system. It came with two remotes, one normal remote and one with a full keyboard and mousepad.

Mounting The Android TV Box

I decided to mount my android TV box on the ceiling, above the monitor next to my shelving. Here, it’s out of the way, the cable runs are short, and I can read the screen on the front face of the unit.

I had to get creative for the mounting of the android TV box inside my van. I used a thin (3/8″ or so) sheet of wood and cut it into a rectangular shape, roughly 5″x8″. I rounded the edges on the belt sander to make them smooth. Then, I placed the android box on top of the wood piece to se where it should be mounted. I choose a spot, and drill two screws in line with each other along one of the narrow sides of the board, bout a half inch in. I place the android box against the screws and mark the backside of the unit on the board. Here, I install a hanger hook. The android box fits snugly between these three points, but I still need to hold it down with something. I use shock cord for this. I tie the ends to the screws and then pull it over the hanger hook to secure the android box to the mounting board.

I drilled out two holes to mount this board to the ceiling. These screws will sit above the android box, hidden when it’s installed. I’ll also use the same drywall screws that are used to mount the cedar planks to the ceiling. I’ll measure them from center to center, transfer this mark to my mounting board, drill pilot holes and then mount the board to the ceiling using the existing holes through the cedar plank ceiling.

Mounting The External HDD

This is kinda tough to explain. You should really just watch the video I made that shows this part in detail. But if you want to read my attempt at explaining it, well here you go.

The external HDD came with a soft neoprene case, with a sort of “flip top”. I flipped the top open and back, now the top faces the ground and the large part of the pocket, where the HDD fits, faces up. I cut a thin (1/8″ or so) rectangular board that would fit inside of the top part of the neoprene case that now faces down. In other words, if the little board was mounted to something, the neoprene case could just be slid over the board and sit on top of it.

First, I make a vertical slit into the front of the neoprene case with a knife, about 1-2″ wide. I drill holes through both the neoprene case and the mounting boards behind it. I get some screws started in the holes, then mount it to the shelving above my monitor’s swivel arm, and below the media center on the ceiling.

Once the case is mounted to the shelving, I add a thin piece of neoprene as a backer inside the neoprene case, to protect the backside of the HDD as it slides against the screws that are used to mount the case. The HDD just slides into the pocket now, with easy access for cables and frequent removal.

Can I Use An Android TV Box In My Camper Van To Power A HDD?

The above is what it all really boils down to for me. I had to figure this out on my own. The answer is yes!

The HDD itself draws very little power. Less than .2 amps. So here’s my power setup for the Media Center:

Anker 36W Dual USB Car Charger Adapter

5v DC Power Cord For Android TV Box

Each of the two USB ports on the Anker charger is 18W, which can support 3.6amps at 5v, which is what the android box runs on. The android box inly uses about .2 amps on it’s own, though. So if 3.6 amps is being sent to the android box, and it’s only using .2 of those amps, it has some extra to pass on to the HDD. That’s great news, because we don’t want to have to plug in an extra HDD, when the android box can power it on it’s own through the same cable that data passes through. The android TV box and the HDD combined, I see about .3 to .45 amps being drawn, which is minimal.

Using The Media Center

I plug the android TV box and the monitor into the same 2-outlet bank, controlled by one switch. So, I an flip one switch and turn on the monitor, android TV box and the HDD simultaneously. Cool.

The android box boots to a familiar android operating system with a series of apps to choose from. KDMC (Kodi) is the main app I’ll use for my media. This is a media center app, and it allows you to specify an external drive to scan for media. It finds my 4TB HDD and boom, there’s all my shows and movies! It’s really that easy.

Because it’s android, there’s a ton of apps to choose from and there’s a bunch of cool things you can do with this device. For example, I’ll be bringing my guitar on my next trip, and I’ll want some guitar tabs to play along with. So, I found an app that reads guitar pro tabs, and I load up my collection on the android box. Now, I can play along to guitar tabs as they scroll across my monitor. Pretty damn cool!

Previous Van Build Project: 16 – Computer Monitor | Van Build Project Index | Next Van Build Project: 18 – Cell Signal Booster

Chevy Astro Camper Van Build: Computer Monitor

Chevy Astro Camper Van Build Phase 16: Computer Monitor & Swivel Arm

Tools & Materials

Materials:

Gigabyte G27F Monitor

Swivel Arm For Monitor

Ratchet Straps w/ Carabiners

Tools:

Dewalt Cordless Impact Driver

1/4″ Drive Quick Release Bit Extension

Craftsman Socket Set

Craftsman 3/8 Drive Drill

Drill Bit Set

Tape Measure

Video – Chevy Astro Camper Van Build: Computer Monitor

Project Overview: Computer Monitor & Swivel Arm

I went with a computer monitor over a TV in my van, because I found the Gigabyte G27F Monitor which comes with a DC plug instead of AC. Perfect. I won’t have the features of a smart TV though, which is unfortunate. To counter that though, I’ll simply run an Android TV Box as my Media Center. More on the Media Center setup in the next phase of the build. It’s a 27″ 1080p monitor with built in speakers, 2 HDMI ports and 2 USB ports.

To mount the monitor in the van, I’ll use a swivel arm. It will be bolted to the reinforced, vertical frame of the shelving above the power center. Mounting the swivel arm here will allow me to swing the monitor towards every available angle in the van, and even outside of the van’s side door if I were standing outside.

TV vs Computer Monitor In A Campervan Build

You want to watch tv and movies, but also want a big monitor for your van’s work station. WFV, work from van. Well, most TVs use AC power, and would need an inverter to use in a van. You don’t want to do that. Inverters are only about 70% efficient, so the power draw becomes 130% more. This may not be a big deal for your setup, but ideally, you want to minimize the things you run off an inverter. They should be more of a “last resort”. Try to run everything off the van’s 12v DC system instead. There are a few TVs that are powered by DC, but they are pretty crappy looking.

The Gigabyte G27F Monitor is one of the few good monitors out there that ships out with a DC power cord, so I can just plug it right into my van. The monitor itself doesn’t have the built in features of a smart TV, but I’ll run an Android TV Box instead. The benefit of the Android TV box over smart TVs might be that the android box is going to be more customizable, especially if you are tech savvy.

Mounting The Swivel Arm

Mounting for the swivel arm begin a few steps back, when I built the shelving above the power center. I had the foresight to use a 2×4 here, instead of the 1″ and 3/4″ stuff I was using throughout the rest of the shelving build. I knew I’d mount the monitor there, so I reinforced the area. These monitors can weigh over 10lbs, and will be hanging 18″ off the shelving. A thin board will not hold this kind of weight over time.

The swivel arm came with some decent heavy duty lag bolts, so I used those to screw it into the side of my shelving after picking a height and leveling it. There’s actually little level built into this swivel arm, which is pretty cool. Not only does it help mounting it level, but the level will also be useful in the future when parking at campsites and such.

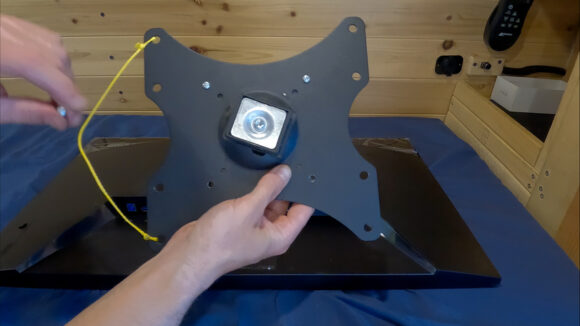

Mounting The Monitor

Mounting the monitor to the swivel arm is pretty straight forward. I have to remove a desk stand from the monitor, that’s how it was shipped. Then, I install the mounting bracket from the swivel arm to the back of the monitor itself. Most monitors have a universal screw layout on the back, so that these brackets can be made for a universal fit. Mine line up perfectly.

On the back of the mounting bracket, there’s a square tab that is mounted in the center, and pivots. This is how the unit tilts, and it’s also the piece that fits into a slot on the swivel arm. You can add a screw into the side of the little slot on the arm to secure the monitor to the frame for extra security.

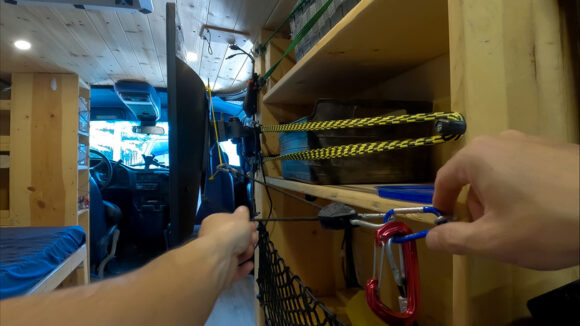

Securing The Monitor While Driving

Because the monitor is mounted to a swivel arm, it will move when the van moves, and fly forward when braking hard. This is not good. To keep the monitor from moving while driving, I’ve devised a simple solution: Adjustable Rope Hangers and carabiners. On the back of the bracket that mounts the monitor to the swivel arm, I’ve attached a length of string spanning two of the screw holes. On the rear side of the shelving, at a height equal to the middle of the monitor, I install a screw eye. Then, I attach a carabiner to the screw eye. And finally, I use the adjustable rope hangers to connect the string on the monitor’s mounting bracket to the screw eye’s carabiner. These little mini ratchets work great for quickly tightening up the slack in the line, making it secure. And to remove, there’s a little quick release tab that makes adding slack o the line fast and easy, and removal is a quick as opening the carabiner when I’m ready to use the monitor.

Previous Van Build Project: 15 – Window Coverings | Van Build Project Index | Next Van Build Project: 17 – Media Center

Chevy Astro Camper Van Build: Window Coverings

Chevy Astro Camper Van Build Phase 15: Window Coverings

Tools & Materials

Materials:

Scotch Heavy Duty Adhesive Velcro

3M 90 Hi-Strength Spray Adhesive

Roll of Reflectix

Black Felt

Refelctix Tape

Magnets

AVS VentVisor Window Visors

Cardboard for making templates

Tools:

Scissors

Permanent Marker

Tape Measure

Video – Chevy Astro Camper Van Build: Window Coverings

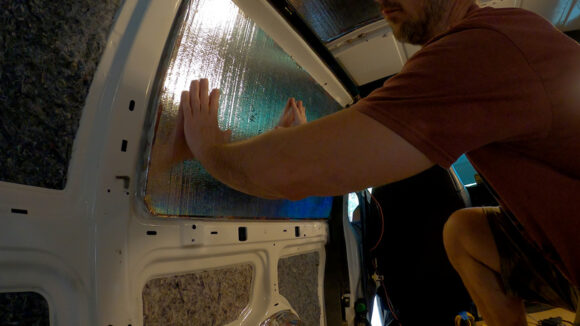

Project Overview: Window Coverings

Windows coverings are essential to any van build. But for the stealth camper van, there are some things you can do to make your van even stealthier.

To make my window coverings, I use use a roll of Reflectix and black felt. They are held up to the van with magnets. It’s a pretty simple system, and it works extremely well. If you have a VentShade for your front windows, and you SHOULD, then you can modify your front window coverings to have tabs/cutouts that allow for airflow so that you can crack your front windows. With the VentShade, your windows can be cracked , and with the tabs cutout from the top of the inside window covering, nobody can tell from the outside, it just looks like one solid black tinted window. Stealthy.

Making Templates

First, you’ll want to cut some template out of cardboard for your window coverings. Trim the cardboard down to fit the window opening as closely as you can… not just the glass, but the metal part of the body alongside the window too… this is where the magnets will go. Make one for each window.

Cutting Reflectix

Next, lay the templates over your roll of Reflectix. Cut out the templates, making sure to leave extra material just to be careful. The window coverings will shrink a little over time, so if they overlap now, that’s ok.

Taping On Magnets

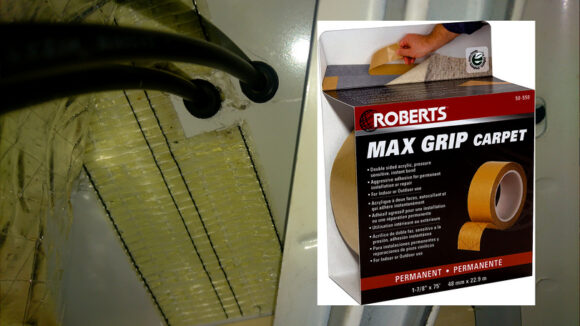

Now I’ll add the magnets. I’m putting 3-4 magnets along the sides of the smaller, rear windows, and more along the larger side and front windows. Put magnets on the corners at least, and then as many as needed in between to achieve a firm fit over the window. Tape these magnets to the Reflectix using, you guessed it, Reflectix Tape.

Glue On Black Felt

Here’s where the window coverings get more, uh, stealthy. What do you think would stand out more: a van with all its windows lined with Reflectix, or with dark tinted windows? Yup, the shiny reflectix. So, I’ll glue some black felt to the outside face of the Reflectix to mimic the look of dark black tinted windows. Sure, up close you can tell it’s not window tint, but really, only from a couple of feet away.

I use 3M 90 Hi-Strength Spray Adhesive here to glue the felt to the window coverings. The easiest way to do this is to spray both the Reflectix and the felt, then sandwich them together, with the felt on the bottom. After they dry, use a pair of scissors to cut the window covers to shape.

Installing the VentShade

Before I can finish my front window coverings, I need to install the AVS VentVisors. These side window deflectors let fresh air in while keeping rain out. It also helps to keep the sun out of your eyes, reduce interior wind noise and fogging, and reduce interior heat. And finally, they allow a stealth camper van to have it’s windows open at night for ventilation, but to anyone outside, the windows look like they are completely rolled up.

The installation of the VentVisor is easy. It comes with an adhesive tape on the back of the visor. Clean the paint on the van with rubbing alcohol to prep the surface where it will be mounted on the door, above the top of the window. Line up the visor and press the adhesive tape onto the body. Done.

Cutting Tabs For Airflow On Front Window Coverings

With the VentVisor installed, now I know how far down I can roll my window before it can be seen from the outside, as it dips below the VentVisor. I then roll the window up slightly from there, and transfer this mark to my front window coverings. I cut out all of the material along the top of my front window coverings, except for the tabs I leave so that I can mount magnets to them. I cut off about 2-3″ from the top of the window coverings, and this now allows airflow to enter the vehicle while the windows are cracked and the coverings are up. This works great in conjunction with my overhead fan for ventilation.

Foldable Windshield Sun Shade

I just used an off-the-shelf Foldable Windshield Sun Shade to cover my front windshield. I just used the normal, reflective sun shades for this, because having a dark tinted front windshield would be weird and stand out. For a stealth camper van, you want to blend in. This folds up and I’m able to store it out of the way, next to/behind my driver’s seat.

Previous Van Build Project: 14 – Passenger Swivel Seat | Van Build Project Index | Next Van Build Project: 16 – Computer Monitor

Chevy Astro Camper Van Build: Passenger Swivel Seat

Chevy Astro Camper Van Build Phase 14: Passenger Swivel Seat

Tools & Materials

Materials:

Swivel Seat Base For Astro/Safari

Tools:

Craftsman Socket Set

Dewalt Angle Grinder

Dewalt Cordless Impact Driver

1/4″ Drive Quick Release Bit Extension

Craftsman 3/8 Drive Drill

Video – Chevy Astro Camper Van Build: Passenger Swivel Seat Base

Project Overview: Passenger Swivel Seat Base

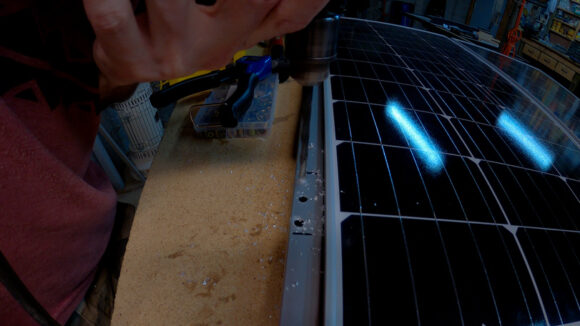

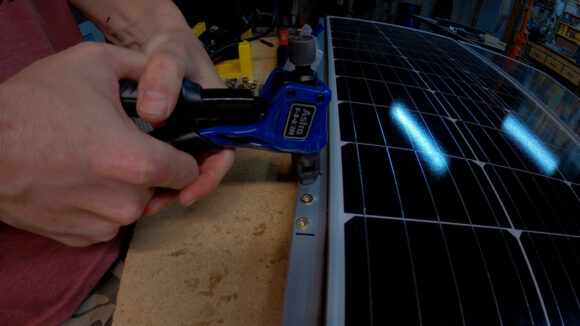

To install a swivel seat base for your passenger seat, we can break this down to 5 steps: remove the passenger seat, remove the seat’s sliding track (sits in-between the seat base and the seat itself), install the sliding track on top of the new swivel seat base, install the passenger seat on top of the swivel base and track, install the passenger seat back in the van. Unfortunately, the sliding track is riveted to the seat base, and you will need an angle grinder and/or drill to remove the rivets. You’ll replace the rivets with bolts later, to avoid this debacle in the future. Besides removing the rivets, which is a pain in the ass, you’ll need a socket and/or wrench set.

The official installation instructions for the swivel seat can be found here:

https://files.cargocollective.com/c1283167/AstroSafariInstall-Small.pdf

Remove Passenger Seat

There’s 4 large nuts holding the seat to the floor. Perhaps 19mm, from memory. These weren’t too hard to get off, since I’ve already had these rusty old nuts off a few times throughout the van build. If you haven’t done this yet, it’s not a bad idea to take some WD40 and spray your threads, and even take a wire brush to them, to make them easier to remove in the future.

Remove Seat From Seat Base & Track

First, remove the bolts holding the seat base and sliding track to the seat itself. There should be 4 bolts, make sure to save these, you’ll need to reuse them.

Remove Rivets Holding Sliding Track to Seat Base

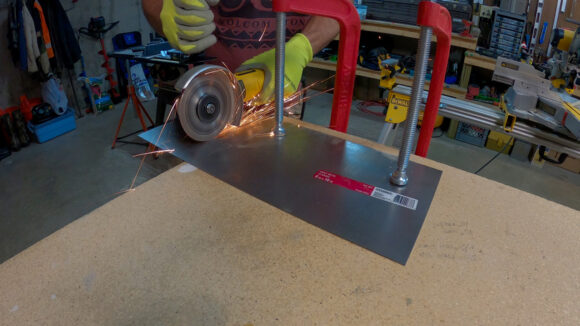

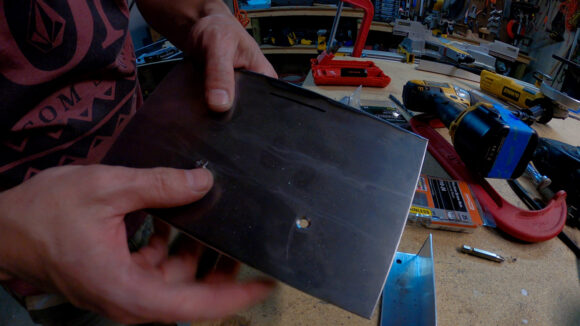

This is the worst part of the swivel seat installation process. The seat track is secured to the base by rivets, and these will need to be removed. There are a couple of things you can do to get the rivets out: use an angle grinder to cut slots in the top of the rivet, use an angle grinder with flap disc attachment to grind the tops of the rivets down, drill them out, and use a hammer and punch to aide in the “pushing” of the rivets out of the holes if the heads are sufficiently removed.

Attach Sliding Track To Swivel Base

After the rivets are removed, the sliding track should be free of the seat base. Now, drill out the rivet holes to 5/16″, to accept the new bolts. We sure as hell aren’t putting rivets back in. Use the bolts that come with the swivel base to fasten the sliding track to the new swivel seat base.

Install Passenger Seat Back Into Van

Finally, install the entire passenger seat assembly, complete with new swivel base, back into the van. That’s it, the swivel seat is in. Time to, uh, swivel.

Previous Van Build Project: 13 – Dometic Electric Cooler | Van Build Project Index | Next Van Build Project: 15 – Window Coverings

Chevy Astro Camper Van Build: Dometic Electric Cooler

Chevy Astro Camper Van Build Phase 13: Dometic Electric Cooler

Tools & Materials

Materials:

Dometic CFX28 Electric Cooler

Dometic CFX28 Insulation Cover

Tools:

None!

Video – Chevy Astro Camper Van Build: Dometic Electric Cooler

Project Overview: Dometic Electric Cooler

For me, having some type of fridge is a necessity for long term van living. Dometic is probably the most well known name in the electric cooler market. Many/most of the smaller van builds are using something like an electric cooler, if not a mini fridge or even larger. For me, one person in an Astro van, I’m going with a 28L Dometic electric cooler. It also has a freezer function that I have never used once. The 28L model I bought is no longer available, and the closest options now are 25L and 35L.

Wrapping the Electric Cooler In The Insulation Cover

The insulation cover fits pretty well over the cooler. There’s a few pieces of Velcro and a couple of zippers to keep the cover in places and tightly fitted over the cooler itself.

Choosing The Location Of The Cooler

When I first started my van build, I was thinking the cooler would go in the very back of the van. For some reason, I envisioned opening the back doors all the time and having that be my access to the cooler. But as the van build went on, I realized that is a terrible place for it. Where will I be most of the time, while in the van? Driving, or in the passenger swivel seat. So, I think it makes sense to put the cooler in-between the front seats. I can access drinks and food while I’m driving, and from my main lounging spot inside the van when at camp. Sure, it prevents me from moving from the drivers seat over to the back of the van with ease, but I can do it if I really want to. No matter where I park, I’d open the side door anyways, to place my water jug outside of the van, and maybe a few other things.

Electrical Connection

Dometic electric coolers can be hooked up via AC or DC power. My cooler came with both an AC and DC power cord, and so I was able to plug the cooler right in to my 12v sockets I installed some plugs in the lower portion of my shelving, behind the driver’s seat, specifically for the cooler. This way, most of the length of the cord can be tucked away and out of sight.

One thing I noticed about the cooler is that the male prongs on the plug need to be bent out a little so that they make better contact with the female side of the plug. I’ve come back to my van a bunch of times and had the cooler be off, as I slightly brushed against the cord perhaps, on my way out.

Using the Dometic Electric Cooler

I wasn’t sure what to expect as far as power consumption goes, but the cooler doesn’t draw too much power. How often the compressor runs will depend on how hot it is outside, if it’s in direct sunlight or not, if you’ve had it open for a while and/or recently put hot/warm foods inside. The compressor can draw 3-6 amps when running, but will only run for a few moments at a time. It may not run for hours, if the temps are cooler.

For me, one person, I can fill up the cooler with food and have it last about a week, or a little longer. This, of course, is a supplement to other foods that don’t need to be kept cool.

Previous Van Build Project: 12 – Shelving & Storage | Van Build Project Index | Next Van Build Project: 14 – Passenger Swivel Seat

Chevy Astro Camper Van Build: Shelving & Storage

Chevy Astro Camper Van Build Phase 12: Shelving & Storage

Tools & Materials

Materials:

Tool Box

Cargo Netting

Bungee Cords

Dimmer Switch For LED Puck Lights

12v DC Dimmer Switch

12v LED Light, Flush Mount

Shock Cord

Sikaflex 715

Wire Loom

Spax Construction Screws

Tools:

Dewalt Oscillating Tool

Dewalt Angle Grinder

Dewalt Orbital Sander

Dewalt Cordless Impact Driver

1/4″ Drive Quick Release Bit Extension

Wire Wheel Attachment

Air Tools

Craftsman Socket Set

Long Clamps For Woodworking

Hole Saw Kit

Speed Square

Video – Chevy Astro Camper Van Build: Shelving & Storage

Project Overview: Shelving & Storage

The main components of the van build are now done. I have insulation, flooring, walls and ceilings. The All of my electrical components are in place. I have a bed. Basically, all of the things I need to function are done. Now, it’s time to turn the rest of the available space into usage storage.

Shelving and storage in a camper van takes some thought. Making use of vertical space is probably the single most useful thing I can tell you about planning your shelving and storage layout. You need a place to store things, while not compromising floor space, if possible. The deeper your shelves are, the more interior space you lose. So it’s a compromise.

I chose to build shelves above my power center and behind my bed. Additionally, I’ll have plenty of storage under my bed. The shelving above the power center will be for my clothes, hiking gear, food, camera gear, toiletries etc. The shelves next to my bed will be for things like my glasses, remote control for media center, hat and various odds and ends that come and go in the cubby holes. The shelves between the bed and driver’s seat, that go floor to ceiling, will be for books, food and various things I want to keep close to me as I drive. The bottom section of the shelves will be open, to access the deeper space behind it, and taller. Here, I’ll keep my backpack that I store my laptop in.

Building the shelves, as well as all of the other woodworking projects in a camper van build, is much easier with a good workshop. I had access to a nice compound miter saw with sliding arm, table saw, belt sander, drill press, router… basically most things needed for woodworking. At a minimum, you need a table saw to rip long boards, and a miter saw (or circular saw) to do chop cuts. To make cuts that follow the contour lines of the van, it’s pretty necessary to have a jigsaw.

I highly recommend sanding the edges of all of your shelves down and rounding off the sharp corners. With sharp corners/edges, you WILL cut and nick your fingers, knuckles and hands from time to time as you reach into the shelves to grab something. It’s a nice touch to add extra comfort to your setup. I’ll be living in this camper van, so better make it comfortable.

Underneath the bed, I’ll store things like tools, towels, hiking and fishing gear, and a tray or two dedicated to my rock and mineral finds. I’ll use a series of open-top baskets/trays for this. It’s a bit of trial and error, buying a bunch of them from the store, and seeing which combination of bins fits the best for my space. Then, I just return the ones I didn’t use.

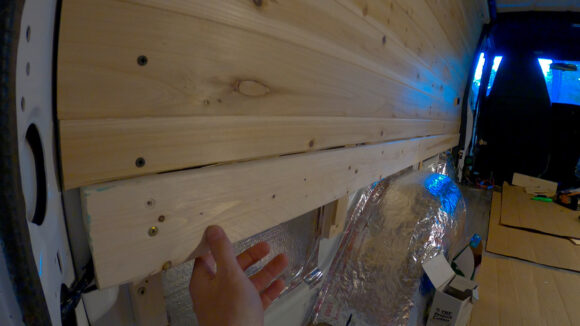

Build Shelves Above Power Center

First I start by cutting a 1×10 piece of select pine board for the vertical ends of the shelves. Because the wall is curved, I’ll need to trim off a bunch of wood along the ceiling and upper part of the boards. This takes at least 10 trips to my basement workshop and back to get right. I trim off a little at a time, mainly using a jigsaw. I’ve screwed down a board across the wall behind the shelving, and this provides a smooth surface for the vertical sides to butt up against, making the trimming somewhat easier as it follows a consistent curvature at the top.

I cut this funky piece (above) to fit around some wires on the ceiling. This piece gets screwed to the ceiling, and provides the horizontal surface for the vertical shelf ends to screw into.

The shelves are pretty basic. I made the bottom one tall enough to fit a 5 gallon bucket, since I’ll be carrying one often on my rock and mineral hunting adventures. I made the middle shelf tall enough to fit a box of Triscuits, and the top shelf gets whatever’s left. Spax construction screws of course, you know by now how much I love these. Notice the space I left on the end. I’ll use this for something else, later on.

Above you can see how I added another cedar plank to hide the ugly transition from ceiling to shelves. This (thankfully) doesn’t have to look too nice, since things on the shelf will hide most of this.

Build Shelving On Side Of Power Center

Like the other side of the power center, I decided to bring the sides in a bit from the ends of the power center. Especially here, where It’d be really nice to have some sort of storage space right here when I open the sliding side door to my van. So, I’ll build some cubby holes and shelves here. First, I need to build a frame. This gives me something to screw the vertical side boards to. Also, I’ll be mounting a swinging arm for my TV monitor here later, so I need this spot to be really sturdy. I use a 2×4 here for this, running vertically.

Next I cut a frame for the top shelving to sit on. Then, I cut the shelf that sits on top of the frame. You can see the odd shape of it in the photo above. Everything in a camper van build is a custom cut piece, like this.

Next I cut a board to mount my dimmer switch for the LED puck lights and battery monitor to. I fasten this to the side of my shelving and run my wires. I use an oscillating tool for the square hole, and a hole saw for the circular one.

After wiring up the dimmer switch and battery monitor, you can really see what a good location this is for these things. Right there when I open the sliding door on the van, which is how I always enter it. I add some trim pieces of wood along the edges of the vertical board, which turns the side shelving into a cubby hole of sorts. It will make a great place to store things that I use every day, and will need as I enter and exit the van… toothbrush and toothpaste, soap, hand wipes, watch, light, knife, etc. Additionally, I’ll use this space to lay my chargers and charging cables in while they are being charged or not being used.

Building Shelves Behind The Driver’s Seat

These shelves will go from floor to ceiling. They will only be as wide as the distance between my bed and the driver’s seat. Those who like to lean their seat way back won’t get much shelf space. A modest lean gives more storage space, so that’s what I go with. Again, I use select pine boards from home depot here. I use 48″ clamps to keep the boards together while I lined them up. I use the tall board in the back to keep the three side boards straight and aligned.

I fasten the boards together using spax construction screws. I know I’ll put some books in the top shelf, so I use them to make sure there’s enough vertical height for them.

Above, I’m laying the back piece for the shelves. I want the bottom part of the shelf to be taller, and not have a back to it. This will allow me to storage things deep in the cavity behind the shelves, under more shelves that I’ll build later, behind/above my bed.

When I try to put the shelves in the van, I realize they don’t fit. Well, the dimensions are right, but I forgot to account for the fact that I would need to turn/twist the shelves to fit them into the space I want them in. This can’t be done when the shelf has a width of 12″ or whatever, it can only be done when the shelf has no top and side pieces. So, I need to putt it out, disassemble it, and reassemble it in the van.

I’ve gotten the shelf in place and standing upright, and have put the top piece back on at this point. Now, I need to fasten the side board again, before I can slide the shelf into place behind my bed.

After reassembling the shelf, it slides into it’s place perfectly. You can see how the bottom is open, hopefully this makes sense now. I can easily access that “large” space for storage because the shelf has no back to it there.

The photo is dark, but it shows the two 12v outlets I wired in here at the top of the bottom opening. These plugs will power my fridge/cooler and my laptop

Sanding Edges Of Shelves

Sanding the edges of your shelves and woodworking inside the van is a nice touch to a camper van build. Don’t scoff at this. You will be living in this van for weeks and months on end, and every time you reach your hand into the shelf to grab something, you’ll appreciate the rounded corners over sharp, jagged edges and splinters. I use a belt sander and/or orbital sander to round the edges of my shelves.

Build The Shelves By My Bed

Now I’, left with a space behind my bed, between the backside of the shelves I just built and the wall. For this space, I plan to build another series of shelves for storage. The design is simple: I’ll build a frame out of 1x2s, screw them together, and slide/wedge it in place between the wall and shelves, the screw it to the backside of the shelves. I won’t screw it to the wall at all, so it will just be held by the screws on one side, along with the force of being wedges in-between the wall and shelves.

Above, I’m sliding the shelf’s frame into place. I’ll be able to add a support board below the frame on the wall here, because there is wood behind the wall here for support. But, not so higher up.

I want the bottom part of this shelf to open, so I can access the storage underneath, from my bed. At first, I use hinges, as shown above. However, these hinges are not going to hold up long-term. These are tiny screws biting into the side of plywood. It’s just not going to last.

Instead of the hinges, I use blocks of wood below the top part of the shelf for support. These blocks of wood allow the top part of the shelf to rest perfectly flush with the bottom of the shelving, and act as a stopper. I attached a thin piece of fabric to one side of the top piece, so all I need to do is pull this up to remove the top when needed. No hinges are necessary, the top just moves freely when needed.

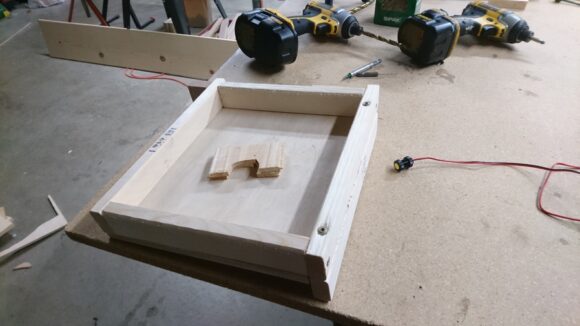

Next, I build another similar frame and shelf system for the middle. This one, and the shelf above that, will have Flush Mount LED LIghts built in, to light up the cubby holes. Obviously I cant just drill through the bottom of the shelf itself to mount the light, so I build a mounting system that gives me a little clearance. A couple of scrap wood pieces accomplish this. I drill a hole in on, to mount the light through. Other wood pieces below this are cut to a half circle shape, making spacers behind the wood piece with the LED light in it. I route the wire through a hole drilled out the back of the shelving, which will run towards the backside of my driver’s seat.

Above, I install the dimmer switch for the LED lights in my shelves. The dimmer switch unit is square, so I had to cut a square-ish hole into a block of wood to mount the dimmer in/on. Then, I use drywall screws to fasten it to the wall.

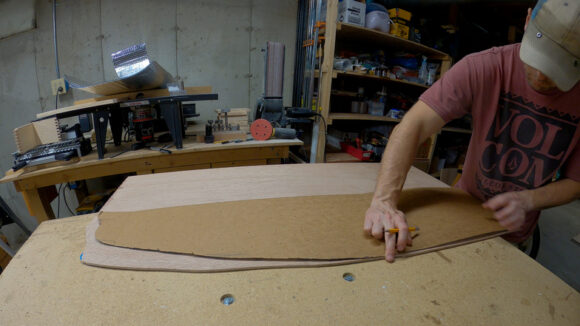

Next I’ll cut a thin board to finish off the backside of the shelves, behind the driver’s seat. This wood becomes the back of the shelves I just built above my bed. I start by making a template out of cardboard, and transferring it to the board. I use a jigsaw to make the cut. This takes several attempts, taking a little off at a time, to ensure I don’t take too much off and ruin the board. Eventually, it slides into place for a fairly tight fit. You could use many things to secure this board, such as panel nails, tack nails or Wire Nails.

Above is a look at the shelves above the bed, complete. Because I hadn’t run wire behind the cedar plank for the simmer switch, I had to run my wire on top of the panel, a much less desirable solution. I made it look OK by wrapping it with some wire loom. Also notice the MaxxFan’s remote mounted here. I used a rubber/neoprene type material to line the bottom shelf with for grip. I also placed some little hooks on the underside of the middle shelf, to hang things from.

And finally, above you can see the bottom piece of my shelf and how it flips up to access storage underneath.

Netting For Shelving

So you’ve built yourself some shelves. But how do you keep stuff from falling out when you drive? Especially down rough dirt roads? Well, this is my solution; nails and Shock Cord. I used nails on the side faces of the shelves, and ran flexible shock cord in between them. This works really well. You can customize this setup to fit your needs… more or less tension, many rows of shock cord or only a few, or only running the shock cord across part of the opening (just the bottom half, for example). It sacrifices zero space from the shelves and costs very little. Shock cord has many great uses so I keep it around for other things too, especially my hiking gear.

For the larger shelves, above the power center, shock cord isn’t going to work. It works great for smaller spaces with less tension. For my largest, lower shelf, I’ll just use this Cargo Netting. This works great here, because many things I’ll put on this lower shelf (like clothes) actually stick out past the shelf itself, and the flexible cargo netting allows the storage space to essentially expand to fit your needs, within reason of course. The cargo netting came with a ton of these awesome plastic J-hooks, which I haven’t seen sold anywhere else expect through the manufacturer that makes the cargo netting (Organized Obie). Obie sells the J-Hooks for $1.05 each, with a minimum order of 10, and they don’t come with the screws. So when I rain out, I just bought some screw eyes instead, as these are cheap and easy to find anywhere. I used the J-Hooks and screw eyes to attach a bungee cord across the opening of the top two shelves. This provides enough surface area and tension to keep things in my shelves in place. I try to use bins, trays and boxes to store small items, instead of loosely placing them on the shelf. By Only placing bins and trays in the shelves, it’s easier to keep everything in place as well as organized.

Storage On Rear Side of Power Center Shelving

Above, you can see how I built the shelves in from the edge of the power center. So what will I do with this space? I use it to store taller, vertical items; fishing pole, ice axe, tent poles, etc. I also have a small garbage can attached here with a bungee. I store extra grocery bags here (for my garbage can), fishing reels, and a few other things.

Storage Under the Bed

The space under my bed is perfect for bins that can be slid underneath. The trick is finding the right combination of bin sizes for your space and needs. You can try to guesstimate while in the store, but ultimately, you’re better off just buying a bunch of various sizes and actually fitting them together under the bed. I just returned the ones I didn’t use.

You can see the wood blocks in the photo above. I made these out of oak, and had run a 1″ board in-between these blocks to keep the bins from sliding out from under the bed. However, after a month or so on the road, I realized the boards don’t really do anything for me, as the bins aren’t sliding around much, if ever, even under the worst of conditions. So I removed the boards, but kept the blocks, the blocks do sometimes catch the bins on the edge from sliding and keep them in place. There’s often enough tension between the bins themselves that that these blocks of wood on the outer edges are just enough provide a little help, while not being in the way at all. So, I just left them there, for now.

Previous Van Build Project: 11 – Power Center | DIY Stealth Camper Van Build Index | Next Van Build Project: 13 – Dometic Electric Cooler

Chevy Astro Camper Van Build: Power Center

Chevy Astro Camper Van Build Phase 11: Power Center

Tools & Materials

Materials:

100a Lithium Battery

Battery Monitor

Renogy 12V 50A DC-DC MPPT Charger

Blue Sea Systems Battery Shut-Off Switch

Blue Sea Systems 12v Outlet

Blue Sea Systems 2-Socket Panel

Blue Sea Systems 60a Circuit Breaker

Blue Sea Systems 70a Circuit Breaker

Blue Sea Systems Toggle Circuit Breakers, 20a & 80a

Blue Sea Systems Terminal Fuse, 150a

Blue Sea Systems MRBF Terminal Mount Fuse Block

Blue Sea Systems Fuse Panel

Blue Sea Systems 250a Bus Bar (2)

20ft 4 AWG Flexible Welding Wire

100a Mini ANL Fuse Holder

12-10 AWG Ring Terminals 1/4″

12-10 AWG Ring Terminals 3/8″

4 AWG Copper Ring Terminals 3/8”

4 AWG Copper Ring Terminals 5/16”

12v LED Light, Flush Mount

12v DC Dimmer Switch

Dimmer Switch For LED Puck Lights

Spax Construction Screws

5/16″ Grommets

Heat Shrink Butt Connectors

Wire Crimp Connectors Kit

Spade Fork Terminal Connectors Kit

Tools:

Dewalt Cordless Impact Driver

1/4″ Drive Quick Release Bit Extension

Dewalt Oscillating Tool

Craftsman 3/8 Drive Drill

Craftsman Socket Set

Dewalt Compound Miter Saw

C Clamps

Heavy Duty Wire Lug Crimpers, 10-0 Gauge

Heat Gun

Wire Stripper/Crimper

Klein Tools Cable Cutters

Step Bit

Speed Square

Video – Chevy Astro Camper Van Build: Power Center

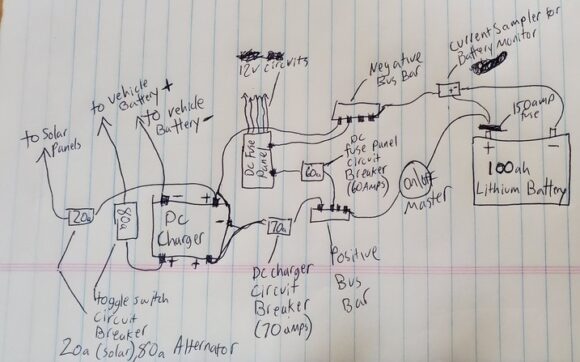

Project Overview: Power Center

The Power Center is the enclosure I’ll build to house all of the major electrical components. All of the van’s wiring will be routed here. The major components are the DC Charger, Lithium Battery, DC Fuse Panel, Circuit Breakers, Bus Bars and a master shut off switch. The power center will have two toggle switch circuit breakers, to turn on/off charging via solar and alternator. There will also be 5 12v outlets installed in the power center.

I’ll need to figure out the most space-efficient way to mount the electrical components. Much trial and error is needed to visualize the optimal layout and design. I originally wanted to include a 1000w inverter, but I couldn’t find a good place to mount it, and decided against it. I ultimately chose to buy a 500w inverter, the kind that’s portable and not permanently mounted. Long term, I am happy with this decision.

I busted out the crayons and drew this diagram of my electrical wiring to help visualize what’s going on. Once you settle on your major components, it’s time to go shopping. Home Depot doesn’t carry practically any of this stuff, but it’s there on Amazon.

Power Center Layout & Design

The first step is to layout all of the components and see how much space they will take up. Things to consider: packing the components into a small a space as possible, keep wires as short as possible, and access to components like circuit breakers. The design of this box takes a lot of thought. What is the best way to utilize this space, given the awkward size and shape of the wheel well? How can I mount these components so that they are protected and out of the way, but also accessible for maintenance?

To start, I lay out my lithium battery, dc charger, fuse panel, circuit breakers, bus bars and a 1000w inverter. I toy with a design that places all of these components on the back wall, and building shelves out over this. Mainly, it’s the big inverter that takes up the largest and most inefficient use of space. I begin to seriously question how much I need the inverter, and ultimately give up on it. Instead, I decide to buy a 500w inverter that’s portable. I can plug it in via 12v DC or direct to the battery with little jumper cables. It takes up less than half the space as the Renogy 1000w Inverter, and I come up with a great storage spot for it later on.

Visualizing the layout of the box. Those components will be mounted no higher than the battery, in an enclosure around the wheel well

Next, I start thinking about a design that has all of the electrical components inside one large “box” that fits around the wheel well. I use some 1×2 boards to visualize the size of the enclosure. I am starting to like this design.

I begin cutting 10″ pine board and make two side pieces, and use a scrap piece to simulate what the front would look like. Yup, this is going to be my design for the power center.

Building the Enclosure

I start framing out the box with the side pieces connected by a board on the floor, cut to fit in front of the wheel well. I’m using select pine board from Home Depot. I’m using the boards I’m using for the largest faces of the enclosure are 1×10 select pine boards from Home Depot. For other parts of the box, I’ll use 1×6, 1×4, etc. I’m using spax construction screws to fasten these boards. Cabinet screws are also a good choice, as they have a flatter head, pulling the boards together tightly without the screw head cutting into the board itself. The downside is that the heads of the screws may stick out a little more than the regular construction screws.

Next, I’ll use metal brackets to join two boards together, creating one board, that will become the mounting board for my DC Charger. This mounting board will sit against the wheel well, and will be recessed in from the front face of the power center enclosure. This will allow the DC Charger to sit flush with the front of the power center when it’s mounted.

Mounting the DC Charger

The DC Charger needs to be visible, because it has LED lights that tell me if it’s on, working properly, and charging my lithium battery or not. But, I want it to be out of the way as much as possible. There are also several 4 gauge wires that need to be routed to and from it. I decide to build a little box around it, essentially, but leave the front open. The cables can pass through on the sides. I prop up the DC Charger with some boards and screw it to the pine board with some spax screws. That’s it for now, until I make some cables to connect it.

Electrical Components Layout

More layout issues. I’ve made the box with a general idea of where the electrical components will go, but now it’s time to do the actual trial and error work of laying them all out in my available space. It helps to visualize the flow of power, from the lithium battery, through the main shut off switch, to the bus bars, the circuit breaks, and to the main components (DC Charger, DC fuse panel). Then you can see which component needs to be placed first inline, and how long the wire connecting one component to the next will roughly need to be.

Once I’ve fine tuned the layout, I start screwing down the bus bars and circuit breakers. In the bottom photo, you can see a hole I drilled through the pine board in the center of the Power Center. This will be used to route wires from the rear of the enclosure to the front. All of my 12v circuit wiring will come in through this one hole, making for a clean installation. Try to be conscious about doing a clean and tidy installation. You don’t want a rat’s nest of random wires tangled up in your power center. When you have problems later on that need to be troubleshooted, or when you want to add to or modify your electrical setup, you will thank yourself when the wiring is ran in a clean, efficient manner.

Installing the Battery Monitor Current Sampler

Next, I’ll install the battery monitor’s current sampler. This thing is exactly what it sounds like: it samples the current, and sends it to the battery monitor. The two big lugs on top are for the for the negative cable coming directly off the battery. The actual current is measured by a smaller gauge positive wire. The ring terminal goes on the battery, before/after the fuse. I’m using a Blue Sea Systems MRBF Terminal Mount Fuse Block with a 150a Terminal Fuse.

Making Cables & Connecting Electrical Components

Next I’ll start on making cables to connect my electrical components together. I’m using 4 gauge flexible welding wire for most of these cables. This wire has an amp rating of 100-150 amps, far more than I’ll need for any single component in my setup. You’ll need Heavy Duty Wire Lug Crimpers, a Heat Gun, razor blade, and Cable Cutters for this next part. You’ll also need 4 AWG Copper Ring Terminals and heat shrink tubing (if this doesn’t come with your ring terminals already).

First I’ll start by making the cable that connects the positive terminal of the battery to the input side of my master ON/OFF switch. I’ll use a razor to cut off about 3/8″ of the insulation from the end of my 4 gauge welding wire. Next, I’ll slide a piece of heat shrink tubing over the wire. Then, I’ll place a 4 gauge copper ring terminal over the end of the exposed part of the wire, and crimp this down using the heavy duty lug crimpers. This tool is absolutely necessary to get a good connection and crimp. Don’t think you will get by using a pair of pliers or something, it’s not going to cut it here! Then, slide the heat shrink tubing over the ring terminal, and use your heat gun to put the shrink on that heat shrink tubing. This provides further protection from the elements and anything touching the exposed part of the wire that may or may not be covered up by the entirety of the ring terminal. Plus, it makes your install look really clean and professional.

Next I’ll cut the cable to length, and put another ring terminal on the other side of the wire.

Some of the terminals in your setup may be 3/8″ and some may be 5/16″. You may need one or the other, or both, of the ring terminal sizes throughout your setup, so be aware of that. They don’t sell this stuff at Home Depot or Auto Zone, so you need to plan ahead and order these things from Amazon, unless you have some excellent local electrical supply store or something.

Above, you can see the wiring coming together now in the power center. You can also see that you need to consider the angle at which you crimp on your ring terminals, especially on such short runs of cable. The two ends might be facing totally different directions, so ALWAYS crimp one end on at a time, and recheck the position of the other end before crimping that one.

Install Toggle Switch Circuit Breakers

Next I cut the hole in the side of the power center for my toggle switch circuit breakers. I’m using a Dewalt Oscillating Tool for this, the perfect tool for the job. I highly recommend buying one for your van build, if you don’t own one already. There will be multiple instances where this tool comes in handy. It allows you to cut very straight and precise cuts in tight environments. There are multiple attachments and uses, but just for it’s unique cutting abilities, I use it all the time. It makes quick work of cutting a hole for the toggle switches to sit in.

These are circuit breakers that are meant to be used like toggle switches. The 20 amp switch will be the master ON/OFF switch for solar charging, and the 80 amp switch will be the master ON/OFF switch for alternator charging. I made a mounting plate for the switches out of some scrap wood. It’s not the prettiest, but it works. And, it looks better from afar!

The switches slide right into the hole, a great fit. On the backside, I’ll connect the cables to the correct switch. Coming into the 20a switch from the ceiling, I’ll attach the 10 gauge cables coming from my solar panels. I’ll use a 4 gauge cable (out of convenience, because I have so much of it) connecting the 20a switch to the DC charger. Coming in from the ceiling, from the vehicle’s battery under the hood, I connect the 4 gauge wire from the battery for alternator charging to the 80a switch. I’ll use 4 gauge wire to connect the 80a switch to the DC charger.

Install 12v Outlets in Power Center Enclosure

I added some 12v outlets to the sides of my power center. You can separate yours into however many circuits as you’d like. The Blue Sea Systems 2-Socket Panel comes with the necessary wiring to wire two outlets together like this, but the Blue Sea Systems 12v Outlet are sold separately.

Connect 12v Circuits to DC Fuse Panel

That hole I drilled through the pine board earlier? Now it’s time to run all of my 12v circuit wires through it. This hole not only provides a way to pass the wires from the front of the back of the enclosure to the front, but also to route them cleanly through on location. The terminals are just below the hole, so it’s a short run and most of the wires sit behind the power center, out of sight. The 12v circuit wires are all 14 gauge, so I use Spade Fork Terminal Connectors for 14 gauge wire. I crimp on the appropriate size spade fork and make the connection to the terminals on the fuse panel. Easy. Also, don’t forget to label your circuits on your fuse panel. The fuse panel should come with stickers for this… use them!

Choosing The Right Size Fuses For DC Fuse Panel

My fuse panel uses the standard sized fuses, and like many people, I already had a drawer full of these amongst my automotive stuff. Fuses are kind of pricey to buy from AutoZone and such, but pretty cheap on Amazon. There’s always your local pick n pull junkyard, too.

It will be up to you to choose the correct size fuse for your 12v circuits. How do you do that? Well, think about how many amps your end appliance will draw. For example, my LED puck lights. I have four 3W lights, for a total of 12w. These lights will draw less than an amp when on with dimmer set to 100%. You want to choose a fuse that is rated for more amps than you will be using, but the smallest amount over what you’ll be using at the same time. For example, a 15 amp fuse is way to high for my LED puck lights. Why? Because if there’s a short in the circuitry and 15 amps are pushed through the circuit, that much juice may damage the LED puck lights, and could melt the thin wires coming off the LED lights. Instead, a better choice for a fuse would be something like 2 amps. That’s much less likely to fry the LED lights or the wires if too many amps slip through.

Now, for something like an outlet, you don’t know how many amps are going to be drawn. That’s up to the appliance you plug in. So here, you should consider the wire you are using in your circuitry. I’m using 14 gauge wire, which is rated for 15 amps. So I’ll use a 15 amp fuse.

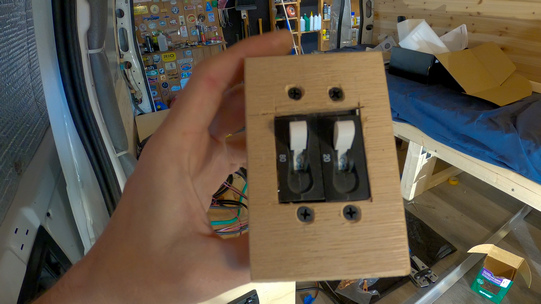

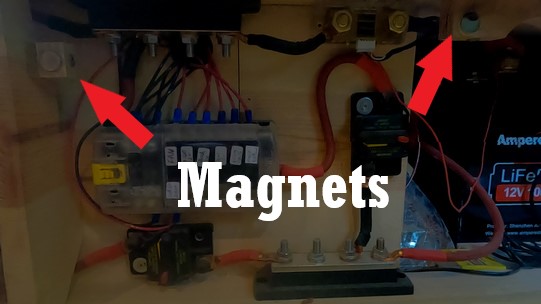

Making a Magnetized Access Door For The Power Center Enclosure

I made a door for the power center that is attached to the enclosure via a hinge on the bottom. I cut out a circle near the top to grab when opening the door. Behind the door, I attached a few blocks of wood to act as stoppers for the door, so it sits flush when placed against the stoppers. Also, I attached magnets to the outer facing edges of the wood stopper blocks. These magnets will contact plates of metal on the inside of the power center’s door when closed. A couple of these magnets together is strong enough to keep the door in place on even the roughest of dirt roads.

Installing the Battery Monitor

The battery monitor is technically installed in the next phase, after I’ve built the shelving. But since it it directly related to the power center, I’ll include it here. I cut a hole in my shelving, next to m dimmer switch for the LED puck lights near the side of the van, and install the battery monitor. I’m using the AiLi Battery Monitor, which has a reputation of being a good bang-for-your-buck battery monitor. This essentially connects to the battery monitor’s current sampler, that I installed earlier. One thing to note about this monitor is that whenever power is being drawn from, or charging to, the battery, the green backlight will illuminate on the screen. This is very annoying at night, as it lights up the entire van. You’ll want some way to cover this up at night.

Previous Van Build Project: 10 – Electrical Wiring | DIY Stealth Camper Van Build Index | Next Van Build Project: 12 – Shelving & Storage

Chevy Astro Camper Van Build: Electrical Wiring

Chevy Astro Camper Van Build Phase 10: Electrical Wiring

Tools & Materials

Materials

Blue Sea Systems 12v Outlets

Blue Sea Systems 2-Socket Panel

100a Mini ANL Fuse Holder

12-10 AWG Ring Terminals 1/4″

12-10 AWG Ring Terminals 3/8″

12v LED Light, Flush Mount

12v DC Dimmer Switch

Dimmer Switch For LED Puck Lights

Spax Construction Screws

5/16″ Grommets

Heat Shrink Butt Connectors

Spade Connectors Kit

Wire Loom

14 Gauge Stranded Electrical Wire

Non-Twist Wire Connectors

Painter’s Tape

Gorilla Glue

Battery Post Extenders

Tools

Dewalt Cordless Impact Driver

1/4″ Drive Quick Release Bit Extension

Craftsman 3/8 Drive Drill

Craftsman Socket Set

Dewalt Oscillating Tool

Dewalt Compound Miter Saw

C Clamps

Heat Gun

Wire Stripper/Crimper

Klein Tools Cable Cutters

Step Bit

Video – Chevy Astro Camper Van Build: Electrical Wiring

Project Overview: Electrical Wiring

**I am not an electrician, and the information I’m sharing here in this post is not meant to be regarded as professional advice. I will not be held liable in any way for harm done to yourself or others by use of the information presented here in this post.**

I’m splitting up the electrical wiring phase of the project into two posts: this one (Electrical Wiring) and Power Center. The power center is where most of the major electrical components are housed, and requires building a cabinet. So I figure, that ought to be its own post. Here, I’ll be talking about the wiring of the 12v electrical system (the lights and outlets), as well as running the 4 gauge wires for my DC Charger (in the next phase) from the back of the van to the engine compartment. This will allow me to charge the house battery via the van’s alternator.

Electrical wiring is something that is not done all at once in a van build. You will find yourself doing a little bit of wiring throughout much of the van build process. I ran what wiring I could prior to installing my walls and ceilings. Then, I connected my 12v lights and sockets while installing my walls and ceilings. Then I had to build my “power center”, where I installed more outlets. Then I built some shelving, and these shelves had more lights, outlets and switches installed in them that needed wiring as they were built. So you see, wiring is something that should be considered throughout the entire build.

For my 12v lights and outlets throughout the van, I’ll use 14 gauge wire. 14 gauge wire is capable of handling up to 15 amps, which is about double what I could possibly use, given my setup, for any one outlet. All of my wiring runs will be less than 20ft, so amperage loss over long runs is not much of a worry.

All of my outlets will be Blue Sea Systems 12v Outlets. Blue Sea Systems makes marine grade electrical components, which means they are a little more water friendly than typical household electrical equipment. I’ll have several 12v sockets throughout the van in various locations. I’ll use 3w LED puck lights in the ceiling, which I’ll control with a dimmer switch. I’ll also have some small LED lights that I’ll build into the shelves by my bed, and I’ll control these with a dimmer as well.

Running the 14 Gauge Electrical Wire

The first step in electrical wiring is figuring out where you are putting what, electrical-wise. Where will I install my 12v outlets? How many will I need? What type of things I will I be plugging in, and how much current will they draw? These are all questions you will need to figure out before moving forward with your electrical wiring.

Now that I have my wall insulation in, I can install my electrical wiring over this. You can read up on the debate between stranded wire and solid wire for your van build, but I chose 14 gauge stranded wire. Mainly, because it’s more flexible, and infinitely easier to run in a van build than solid wire.

I know where my power center will ultimately go, which will house my lithium battery, dc charger, fuse panel etc, so all of the 14 gauge wires that I’m running for my 12v circuitry will all be routed to the same place: the back of the van, on the passenger side. I run wires through the beams on the ceiling to get to the driver’s side, and just use some tie wraps to keep them in place here. I had to drill through the metal beam a couple of times for the wire run, and I used rubber grommets here to protect the wire from the sharp edges of the metal along the hole.

I route the wires through hollow parts of the body where I can. This is pretty easy to do throughout much of the van, especially in the rear. The wires are well protected in here as well and don’t require much work to secure. Tie wraps work pretty well here.

Some of the wiring I’m doing requires some splicing. A good example of this is the shelves I’ll build at the head of my bed. I’ll run one 14 gauge wire here, which I’ll splice off into three 12v outlets and two LED lights. I use some non-twist connectors for an easy, push-in splice job.

The wiring for the lights is done in a daisy-chain fashion, so I run one wire from the power center to the first light, then cut short sections of wire to connect to the next light in the chain, and so forth. I use painter’s tape to tape them wires to the ceiling for now, until they are ready to be covered with cedar planks.

I’m still not exactly sure where all of the components of the power center will actually go, so I make sure to leave a bunch of extra wire rolled up at the ends of my runs to the power center, just in case.

Installing the 12v Outlets

Installing the 12v outlets requires something a little different at each mounting location. Some are easy, and some have less clearance on the backside. The 12v outlet at the head of my bed is a good example. The 12v outlet is a cylinder that’s a few inches long and about the diameter of a quarter. It fits into the square hole in the body, just below the bottom cedar plank on the wall above. However, it needs just a little more depth. I can’t make that hole any deeper, since that’s the outer skin of the van, but I can add a spacer between the cedar plank and the outlet’s mounting plate. This will raise the surface that the outlet sits on, and allow it to fit the depth.

In the photo above, the 12v outlet is wired up and the cedar plank is ready to go up on the wall. Notice the grommet in the wall to protect the wire. I used spade connectors to connect the wires to the 12v outlet terminals.

I made this wood spacer to go behind the outlet’s mounting plate to give me extra clearance in the rear

In the photo above, you can get a better look at the wooden spacer I made here to be able to get the depth behind the wall I need to fit the 12v outlet. I used a belt sander to smooth the edges out as needed, to fit the shape of the mounting plate.

The above photo shows the wiring leading to two 12v outlets built in to the shelves at the head of my bed. I split the wires off here to provide power to two separate outlets.

Install LED Puck Lights

The wiring of the LED puck lights is easy: connect the red wires to red wires, black to black. So… there’s a pair of positive/negative wires coming into the first light, from the power center. I’ll strip off about 3/8″ from the end of my 14 gauge wire, and slide both wires into their own 2-port non-twist connector. Now if you’ll remember, I already cut wires to connect the rest of the LED lights, and taped them to the ceiling. So, all I need to do is take one end of the wire taped to the ceiling and insert them into the non-twist connector port connected to the first LED light. Then, connect the other end of those wires to another 2-port connector, and connect to the second LED light. Just keep moving down the line and connect all of LED lights together in the same fashion.

Install Dimmer Switch For LED Puck Lights

I had to wait until my shelves were mostly complete to install the Dimmer Switch For LED Puck Lights. I used my oscillating tool to cut a nice square hole in the wood for the dimmer. The dimmer switch goes in-between the power center and the LED puck lights, so I just made a cut in my wiring at the appropriate location, and wired up the light. Your dimmer will have specific instructions for wiring, so follow the wiring instructions of your specific model.

Install LED Lights In Shelving

I had to build some special wooden pieces to mount my LED light under my shelving at the head of my bed. There is a certain amount of depth to the light, so I need to build up some space to gain the height I need. Much of the details here lies in the woodworking, rather than the wiring.

With the light mounted, I ran the wiring behind a piece of trim that I sanded the corner off of, to make a recessed area for the wires to sit behind.

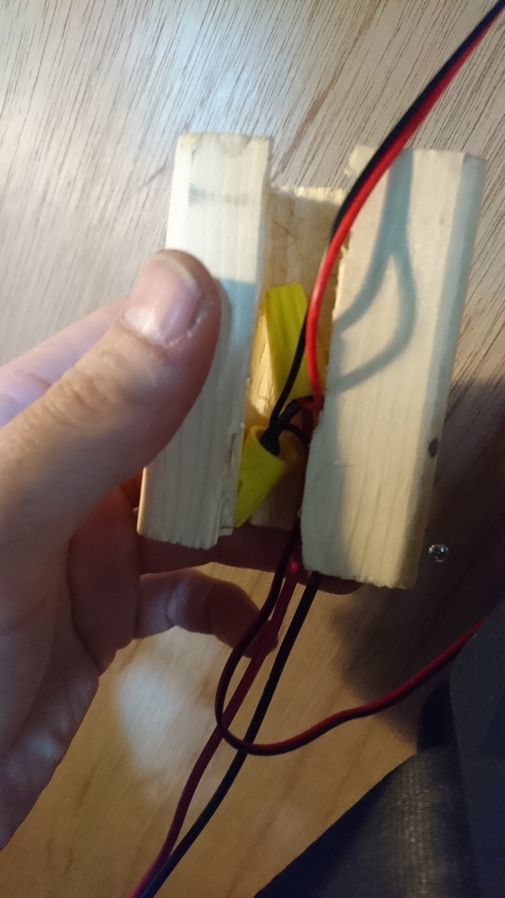

Install Dimmer For Shelf Lights

The dimmer switch is a tiny little square piece, and I struggle to come up with a clean way to mount it. I end up taking a small block of wood and cutting a hole in it to fit the dimmer. I took some time to get the fit right, but it was tight and secure in the end. I also added some gorilla glue to bond the switch to the wooden mount.

Next I screw the wooden mount for the switch into the wall. I use two drywall screws for this. Be careful not to go too tight and crack your mounting piece, or the planks.

Protect Exposed Wiring

For some reason, instead of using some type of junction box, I made some funky wood pieces to protect a couple of the connections in the wiring behind the driver’s seat. I took a drill to a 2×3 block of wood, and drilled out some cavities for the wiring to pass through. I don’t recommend this, but it worked, and saved a trip to Home Depot.

Run 4 Gauge Wire For Alternator Charging

In the next phase of the van build, I’ll build the power center and will be installing a DC charger (more on how that works in the next phase). I’ll run the heavy-duty 4 gauge cables for that now. What I’m doing here with the cables is connecting the DC charger that I will be installing with the vehicle’s battery, under the hood.

I used some flexible conduit to protect the 4 gauge cables as I ran the along the roof, alongside my side door, over to the head liner. I used some tie wraps to strap the conduit to the ceiling.

Next, I’ll need to run the cables above the headliner over to the A pillar. The A pillar is the part of the vehicle’s body that runs between the windshield and the front doors. This piece is usually held on by some clips, or possibly screws. Remove this and run the cables down the A pillar, and put the trim piece back on to cover up the wires.

Next, I use a step bit to drill a hole through the firewall. I don’t want the sharp edges of my hole cutting the cables, so I insert a plastic plug into the hole. Then, I cut slits in the face of the plug and run my cables through that. That way, they are protected by plastic on all sides.

Finally, I pull the cables through the engine bay. I’ll install a 100a Mini ANL Fuse Holder and fuse in between the positive cable and battery terminal. This protects the DC charger from a high voltage spike. The negative cable gets hooked up to the negative terminal. I added some Battery Post Extenders to make it easier to add the extra connection to the post. When adding “accessory” connections to side post batteries, you may find yourself running out of threads for your bolt to grip after adding extra thickness (ring terminals, etc). The extenders help overcome that issue. But I’ll leave this disconnected until I’m ready to connect it to the DC charger, in the next step.

Previous Van Build Project: 9 – Solar Panels | DIY Stealth Camper Van Build Index | Next Van Build Project: 11 – Power Center

Chevy Astro Camper Van Build: Solar Panels

Chevy Astro Camper Van Build Phase 9: Solar Panel Installation

Tools & Materials

Materials

2 100W Solar Panels

Solar Panel Wires Roof Entry Port

Renogy 20FT 10AWG Solar Extension Cables

Solar Panel Y Branch Connectors

Spax Construction Screws

Adjustable Rope Hangers

Aluminum Tubing & Connectors

Sheet Metal Screws

Rivet Nut Set

Hinges

16 Gauge Sheet Metal Plate

Loctite Threadlocker 242

Angle Aluminum

3M VHB Tape

Heavy Duty Waterproof Rubberized Roof Tape

Loctite PL Max Construction Adhesive

Sikaflex 715

Metal Cutting Diamond Blade for Angle Grinder

Renogy 20a Inline Fuse

Tools

Dewalt Cordless Impact Driver

1/4″ Drive Quick Release Bit Extension

Craftsman 3/8 Drive Drill

Dewalt Compound Miter Saw

Rivet Nut Tool

Center Punch Set

Craftsman Socket Set

Dewalt Angle Grinder

File Set

C Clamps

Countersink Bit Set

Video – Chevy Astro Camper Van Build: Solar Panels

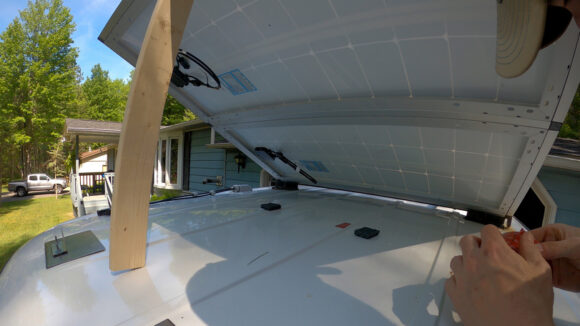

Project Overview: Solar Panel Installation

Mounting solar panels could have been a quick and easy job, but No out-of-the-box solution appealed to me. I did it the hard way and custom fab’d everything from the frame to the mounting brackets. And, I got the wild idea to mount the brackets for he panel with tape instead of drilling through the roof. Sounds like a crazy idea, but after a year on the road, it’s been holdings strong. Maybe I’m not crazy.